A Peep into the History

Before introducing sugar into western cities such as Illinois, Louisiana, Wisconsin, Montana, and New York, honey was the primary sweetening component used to manufacture confections. Honey was incorporated into fruits in ancient China, Rome, and India to provide a sugar layer. Honey was also used as a layer on the fruits to prolong their shelf life.

Earlier, doctor’s chambers were places where sugars were in use. Later confectionary industry emerged enticing journey for our respective taste buds. People love eating sweets making the confectionary industry grow at a rapid rate.

Importance of Sweetening Agents

Sweetening agents are the primary need for confectionary manufacturing. Can you ever imagine your candy chocolate tastes good without the sweetness? Table sugar is a commonly used product that contains fructose and glucose. Sugar derived from the hydrolysis of sucrose made considerable success. It’s a sweeter component and is used more than any commercial baking sweetener.

Even corn syrups derived from starch hydrolysis are a popular sweetener in the confectionery industry. Sugar-free sweeteners are also available depending on the increasing craving for candy products among the diabetic population.

Knowing Baker’s Confectionary

Earlier, we discussed the two types of confectionaries in the confectionery industry. The first one is Baker’s Confectionary, which involves baking sweet dishes like cakes, pastries, cookies, doughnuts, etc. The residents of Illinois, New York, Louisiana, etc., and other American states love savouring such sweet dishes.

- Cakes- Cakes sport a texture that resembles that of bread but can come in various shapes and sizes. The tastes also differ depending on the component added like chocolate, vanilla, strawberry, etc. Different cake variants like butter cakes, foam cakes, cheesecakes, etc., complement your taste buds.

- Pastry: Pastries can be of many types, some as a smaller version of a cake, and some are sweet dough baked and glazed with sugar syrup. They come in all shapes and sizes, requiring minimal ingredients in the making.

- Doughnuts: Another category under the baker’s discretion, is doughnuts that can either get baked or fried. The sweetness of the doughnuts, collaborated with the creamy decorations, can make anyone fall in love.

Knowing Sugar Confectionary

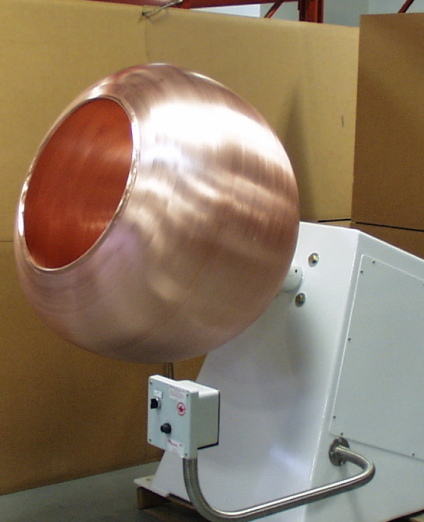

Chocolate candy, sugar candies, chewing gums, and even ice creams are the best example of sugar confectionery. Sugar Confectionaries are widely consumed throughout the world. Back in the day, candies used to be made by boiling sugar water till it got hard and then cooling it into candy shapes. Special candy coating machines are used to layer on various hard candies and nuts.

Today Sugar Confectionery industry is one of the largest and accounts for 39% of candy consumption globally. And they are expected to grow significantly in upcoming years. If you want to start a business, on in sugar confectionery seems lucrative.

ConfectioDiscussing them in detail won’t make sense as it would already make its way inside your mouth before completing!

Confectionary Manufacturing

The crafting and manufacturing process of all the confectionary products like cakes and chocolates require the best modern machinery and process systems for quicker results. The demand remains at an all-time high, and thus the supply has to be higher and more consistent. It takes high-quality raw materials and a wide range of confectionery equipment to create the perfect products.

The best confectionary machine helps manufacture the desired candy chocolates without hassles, giving them the perfect shape and taste. The ingredients get added in perfect measurements that result in the enticing taste results when the candies come out for consumption.

The better the machine design, the easier its operation will be. Confectionary machinery that is easy to operate enables better and faster delivery, unlike hard-designed machinery that requires more effort to grasp its function.

Looking into the production line of the confectionary candy-making equipment emerges as a visual testimony of perfect product development. The candies and cakes get checked during the production line, so no bad product proceeds for packaging.

And after packaging, they reach stores and bakeries near you so you can enjoy your favourite desserts.

Benefits of Choosing the Best Confectionary and Confectionary Machine Manufactures

When you choose the best confectionary and confectionary machine manufacturers, the following advantages eliminate all your worries;

- Top-class confectionary machinery that aids in crafting accurate candy chocolates and other confectionery products.

- Innovation centre and technological support for manufacturing supremacy.

- The tastiest products.

- Support throughout the journey.

Companies have been innovating confectionery machines learning from years of experience. To make machines that produce the best sweets, candy chocolates and perfect sugar coatings on all the pastries. Investing in good confectionary manufacturers will significantly affect product development, and you can have better production equipment.

Final Thoughts

Having a wide range of products crafted from a trusted confectionary makes the task easier for you. Now, you do not have to worry about the perfection of candy or cake shapes, let alone its taste! Do not wait any further to grab the best confectionary machinery and give your dreams a chocolaty and sweetening flight!