Tablet Coating System – Why Do We Need It?

The tablet coating is highly popular in the pharmaceutical industry and can be applicable to a wide range of oral medicines dosages. These forms can be tablets, crystals, powders, pellets, and granules. Although the coating of tablets has been in practice since the early ages, the same is still an undeniable concept in the medical field. The tablet coating machine is an integral part of the modern medicine-making process. Not just the coating process, the advanced machinery, and technologies in tablet coating serve multiple purposes.

The majority of the active Pharmaceutical ingredients come up with variable tastes and odors. For instance, some of them might be very bitter, others can have mild impacts of bitterness. The continuous tablet coating process can take away the unpleasant odor/taste with the help of film-forming agents, flavoring agents, taste-masking agents, and other coating ingredients. Most of the drugs remain highly sensitive to moisture, light, and oxidation, which increases the need for tablet/drug coating. The usage of the stabilizers in the tablet coating ingredients can safeguard the drugs from light sensitivity, moisture, and others. The effective coating process also protects the drugs from further degradation because of atmospheric oxidation.

The tablet coater machine deals with the drugs which remain pharmaceutically inelegant. You can also use pharma-grade pigments or other materials to boost the elegance or aesthetic of the drug. The colored solution can easily make the patient’s clothes and hands dirty, if not used with the right quality and efficient machines. Modern-day tablet coating machines use soluble cellulose materials to coat the tablets. It can also avoid the risk of interaction between two incompatible substances. You also get to modify and control the drug release profile with a tablet coating machine. Such modification is also effective with oral delivery and sustained release systems. The tablet coating machine can mitigate the potential risks and avoid the interaction between two incompatible materials. Hence, a reliable good manufacturing tablet coating system can ensure flawless and effective end results.

Major Processes Involved In The Tablet Coating

Out of the many, there are main three processes with tablet coating as mentioned below –

1. Film Coating

As per the name, a thin layer of polymeric film is used on the product to facilitate the film coating benefits. An automatic tablet coating machine manufacturer provides an industry-driven and robust solution that provides film coating for pharmaceutical products. Although the film coating was in the traditional machines as well, the same is improvised in the modern machines. The latter ones even come up with effective drying, high-level automation, and quick coating benefits.

Film coating on the tablet is a standard and typical element of the production process. These are also helpful in adjusting or postponing the drug/medicine release while contributing to the product stabilization strategy. The production and usage of film coating are helpful in enhancing the product’s appearance, qualities, and intake convenience.

2. Sugar Coating

The sugar-coating process is one of the types of tablet coating contributing to quick-release applications. Sugar coating can be the best way to cover up the bitter flavor and odor of the medications. Moreover, it can also improve the overall characteristics of the tablet and other products’ visual characteristics. You should also note that the coating procedure can impact the dissolving capacities of the medicines. Sugar coating can delay the overall disintegration of tablets in the machines. It can also act as a barrier against the outer pollutants while keeping the internal medication safe inside the tablet.

3. Enteric Coating

Enteric coating is a polymer used on oral medications for covering inner medications. It avoids the dissolution or degradation of the medications inside the patient’s stomach. The standard coating pan can make medicine swallowing easier for patients. The majority of medicines tend to dissolve quickly without enteric covering or protection. Thus, the enteric coating layer can enhance the medicinal effects without being released in the acidic environment of the stomach. The medicine ingredients reach the intestine without any disturbance.

Efficacy Of Tablet Coating Machine

There are a lot of considerable factors to determine the efficacy of a tablet coating machine. The equipment should have the right scale of pressure regulations for effective and reliable coating of the tablets. It must include the necessary features to facilitate the coating process efficiency. Not only will it improve the visuals of the end tablet, but it also adds up the weight of the tablets. The end product remains thinner without any difference in the overall size. The continuous tablet coating process can mask the bitter taste of the ingredient and make it easy to intake for any patient.

A film coating machine safeguards the tablets of the pharmaceutical industry from moisture, light, and efficacy. It can also make the tablets less susceptible to the effect of stomach acids. Without coating the tablets, the acids have the capability to degrade the tablet products. Thus, a tablet coater machine can keep a safe layer on the tablet to protect it from further damage. You should focus on certain factors like the surface area of the tablet before choosing the machine. Go for the one that can produce standard tablet sizes to keep the end product completely flawless.

Another essential factor to consider for finding an automatic tablet coating machine manufacturer is to focus on the formulation and core properties. Regardless of what sort of pharmaceutical tablet, the coating formulation should be completely appropriate for the best results. Otherwise, if the formulation remains incorrect, the tablets might show inconsistent granules. In some cases, the dry film may crack from the tablet, making the tablet unusable. The tablet coating machine should adhere to the top-class industry standards like ISO, FDA, cGMP, and more. Check out the efficacy levels along with durability aspects for long-lasting results.

The ideal film coating machines can have the best efficacy levels with the availability of various optional parts. Having the separate components of multiple processes can be a huge benefit. It should be corrosion-resistant while catering to the technological advancements of the future. The machine manufacturers should follow the cGMP-compliance benefits to maintain the high-quality coating. Dealing with the industry leaders can help in curbing out operating costs while maintaining the best end results.

What is Film Coating on Tablets?

Film coating is the general term for the thin cover applied around a tablet to hide its bad taste. The film coating process does not interfere with the pharmacological components of the drug.

Although the coating of tablets increases both their production and shipping costs, the benefits greatly outweigh the costs.

Chocolate and Candy

Pharmaceuticals

Vitamins and Health Supplements

- The thin layer of coating protects the tongue of the user from bad tastes. This makes it much more likely they’ll be able to take their drugs.

- The coating protects the drugs from moisture and light, which can lower the efficacy of the drugs.

- Drugs can cause irritation and be less effective when released in the esophagus or stomach. The film coating material allows them to release later in the digestive tract.

- The coating also helps with product identity and distinct appearance.

How Much Does A Tablet Coating Machine Cost?

- When you decide to purchase a tablet coating machine, there can be a lot of considerable factors. One of them is spray gun positioning which can impact the overall final coating quality expectation. The size of the batch also matters to process the tablet coating and is another considerable option for your purchase. Pricing can be a leading aspect of the coating system and machine purchase. So, to make it simpler, we are sharing some of the other considerable aspects –

- You should know the number of tablets a batch needs before selecting the tablet coating machine. It is also possible to increase the throughput of the machine to further boost overall productivity. Hence, you can increase the profits in the pharmaceutical industry with better use and control of the machines. You should also assess the current throughput value to understand the bottlenecks. As you can identify the bottlenecks and improve the communication channel, there are high chances of throughput conditions. At Coating Pan, we help you achieve the same level of throughput levels as the traditional batch-size machines. Get all these benefits in a single tablet coating machine while investing a decent amount of money.

- Our film coating machine allows the easy temperature regulation of hot air to boost the tablet coating process efficiency. The coater pan includes the perforated ribs along with a spray nozzle in the coating system. With efficient spray, the coating material can reach the tablet ingredient without degrading the quality standards. However, it is vital to choose the correct coating process and machine in order to meet the industry’s expectations and needs. The inbuilt spray system in tablet coating machines ensures the uniform distribution of coating liquid with high-end precision and quality coating benefits.

Common Functions Of Tablet Coating Machines

- A tablet coating machine is highly convenient for a variety of reasons. From the consistency of the drug to the release speed of coated tablets, tablet coating machines can help in various regards. It also maintains the drug ingredients’ position in the tablet at a fixed position to boost the stability of the end product. Keeping the drug in its original state and form minimizes the problem of oxidative degeneration. Let’s understand some of the exclusive functions and benefits associated with tablet coating machines.

- The automatic tablet coating machine manufacturer provides cylinders with an electric motor that tends to rotate the tablets. Along with this, the heated air sprays onto the tablets can ensure stable coverings on the tablets. It even comes with a perforated coating pan with rotating drums and perforations. The two nozzles in the drum can keep on spraying the liquid onto the rotating bed of tablets. The best spraying systems can assist in reducing clipping and blistering. These can facilitate the even distribution of the coating solution without causing cracks and chipping.

- The tablet coating machines with optimal drying conditions can easily boost the end results of the coating processes. It maintains the right air balance while using the inorganic solvent in the system. All you need to do is to know the chemical composition beforehand to avoid any chance of using the wrong solvents. The coating system places the tablets in a rotating drum and rotates in the orbital pattern. Thus, it can avoid the end result of tablet coating getting thicker or thinner. The pumping of the hot air is what keeps a stable coating on the tablets. Moreover, the fully automatic coating machine also comes with a heating chamber that turns out to be a safety feature.

Major Specifications To Consider For Tablet Coating Machine

- Are you planning to choose the tablet coating machine? There are certain must-have specifications to consider before making the final selection. A good machine/equipment should contain a drum with orbital movement to rotate the tablet. The simple yet essential rotation of the tablets will ensure the ideal and uniform coating benefits. It even covers the entire area of the tablet on all sides to avoid the crack or degradation of the inner ingredients. In addition to the drum roller, the equipment includes an electrical motor, air ventilation, and exhaust to maintain the right balance between the hot air and the cold air.

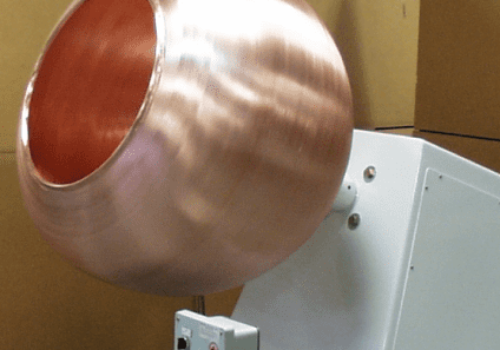

- The perforated coating pan comes with a semi-ellipsoidal shape with a wide mouth or opening. It is kept at an angle of 45-degree from the horizontal surface level with multiple phase levels. The machine will also include the assembly drive, 440-volt, 1440-rpm, electric motor, and gearbox. The peristaltic pump in the tablet coating machine can scale and stabilize the coating solution to create thin layers. The coating solutions are compressed on tablets of multiple sizes. To make the process simpler, the guide plate on the tablet coating machine can deliver the proper directions for tablet formulations and mixing of the substances.

- At Coating Pan, we bring an efficient coating tablet machine with a spray system and automated control system. Since it is self-explanatory, it also becomes simpler to control the coating temperatures for tablets. Our coating pan machines come up in multiple sizes that contribute to the drying expectations. The spray nozzles in the drum can facilitate the atomizing of the coating solution at a huge scale. This makes our tablet coating machine highly efficient in terms of high-end spray and drying benefits. Moreover, the large capacity of the sugar-coating machines is what makes them ideal for the pharmaceutical industry. Moreover, the coating tablet machines contain a high-quality stainless-steel pan for additional benefits.

- Further, the tablet coating machine comes with an insect protection layer to deal with critical parameters, temperatures, air, humidity, spray quantity, and pressure differences. Since the tablet coating can be of any material, you should go with the machines supporting all types of coating processes. At Coating Pan, we provide top-notch and reliable tablet coating machines catering to a wide scale of requirements.

Things To Consider For Purchasing Tablet Coating Machine

- 1. Air Capacity (Amount Of Air): Check the amount and volume of air passing through the tablet coating process. The machine should be able to extract sufficient amounts of water or solvent during the tablet coating procedure. You can always discuss the requirement with us to get the best air capacity and drying efficiency in the tablet coating process.

- 2. Coating Substances: The solvent in the tablet coating process acts as a carrier for chemicals and additional substances. Assess what sort of coating composition and substances are applied to the surface in the coating process. The process follows the air forcing in the coating machine to remove the solvent. The continuous tablet coating machine can maintain the right balance between solvent evaporation and coating liquid. The tablet machine manufacturer can be injected to speed up the process by heating the incoming air.

- 3. Tablet Surface Area: Estimate the amount of coating solution that needs to be applied in the tablet coating process. Calculate the weight of the batch tablets and match it with the amount of coating solution. Choose the tablet machine manufacturer’s machine impacting the size of the tablets and surface characteristics. You can use a substantial ratio of overall area to weight ratio for exclusive benefits.

- 4. Machine Efficiency: Compare the film coating machines’ efficiency with the accumulation of the coating material on the pan walls. The tablet coating machines include various optional items like a WIP system, dry dust collector, electric heat exchanger, interchangeable pan, humidifier, and more.Apart from these, there can be various other aspects to consider before purchasing the tablet coating machine. You can always discuss the scope of the requirements with us to find the perfect automatic coating machine. Stay free from the pricing and feature overburden and get the standard coating machine in no time.

Coating Pan – Trusted Automatic Tablet Coating Machine Manufacturer

- Are you ready to find an automatic tablet coating machine manufacturer? Look nowhere else than Coating Pan in the USA and Canada. We are the leading provider of coating solutions for candy, food, vitamins, tablets, and pharmaceutical products. Coating Pan is an industry leader in preparing metal spinning and sheet metal components for commercial usage. We have been a manufacturer and supplier of top-notch work in the pharmaceutical sector.

- We understand the importance of the tablet coating process in the overall production and development. We help the pharmaceutical sector to cater to the modern-day solution that can serve coloring or taste-making requirements. Our machines come with enteric coatings, controlled release, active ingredients, and more to facilitate the continuous tablet coating advantages. Our extensive experience and expertise come from long years of innovation and development. Our tablet coater machines have set a new benchmark for tablet coating processes including mixing, spraying, and dying.

- Coating Pan is a specialist in providing coating solutions for Oral solid dosage forms (OSD). We have been a leading supplier of innovative machines to the top players across the globe. Our machines come with high-end features and robust practices to achieve higher spray rates in shorter process times. Our team keeps a keen eye on the drum geometry and matching system for hassle-free functioning and benefits. Our perforated coating pan solutions can achieve verified filling levels without the requirement to mix baffles. Regardless of the process support, service agreement, and rental equipment, we are the #1 tablet coating machine provider.

- Coating Pan is an innovation-driven company providing rich expertise in the tablet coating process. Unlike ordinary tablet coating machines, we focus on pursuing new and advanced ways of OSD manufacturing. Our tablet coating machine can offer better productivity and low drying time for tablets. Achieve less handling and more hygienic benefits with uniform drying at low temperatures. Opt for the product container with a high-end tilting arrangement and flameproof models. Discuss your requirement with us and choose the higher capacity models with pneumatic sealings.

- Partner with us for providing cost-effective, high-quality, value-added services, affordable, and proactive solutions. Our fast response to industry trends and innovations can improve solid dosage processing equipment. We remain close to the customers to beat the competition. Contact us today to get the hands-on-involvement at each stage of the tablet coating process. Our team will provide reliable assistance and support with your next purchase from a tablet coating machine manufacturer.